Imaging Tower

- Simplex Configurations

- Duplex Configurations

Simplex

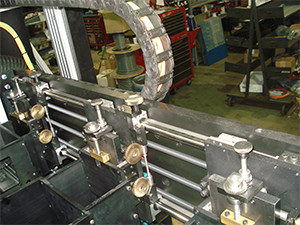

The SI Portable Simplex Imaging Tower is designed for Simplex top or bottom side imaging for Kodak 6240, S10 or S20 inkjet heads. The standard configuration includes 2 rails with (2) motorized carriages with up to (3) buckets per rail for a total of (6) inkjet heads and all of the necessary idler rollers for top or bottom side imaging applications.

A 2nd SI Portable Simplex Imaging Tower may be added for Duplex top and bottom side imaging for a total of (12) inkjet heads. When placed together the pair will image the top and bottom side of the web with (6) heads per side. When placed end-to-end they will image one side of the web only with the ability to use all (12) heads.

Duplex

The SI Portable Simplex Imaging Tower with Single Drawer Extension Module is designed for Duplex top and bottom side imaging for Kodak 6240, S10 or S20 inkjet heads. The standard configuration includes 4 rails each side with (3) motorized carriages with up to (3) buckets per rail for a total of (12) inkjet heads and all of the necessary idler rollers for top and bottom side imaging applications.

A 2nd SI Portable Simplex Imaging Tower with Single Drawer Extension Module may be added for Duplex top and bottom side imaging for a total of (24) inkjet heads. When placed together the pair will image the top and bottom side of the web with (12) heads per side. When placed end-to-end they will image one side of the web only with the ability to use all (24) heads.

Standard features include:

- The upper frame contains the imaging head bucket drawers that are mounted on linear bearings with full length slides to extend into the operator side aisle for servicing of the inkjet heads.

- Carriages are fitted with manual adjustments for up and down and web direction movement to aid registration when using non-Kodak software

- Individual motorized side-lay movement of carriages for stitching positioning (1/2 dot per 600 DPI resolution)

- (1) Driven water-cooled chill roll with color touch HMI and control station for motor speed control

- Frames are prepared for an optional 2nd chill roller.

- Designed to accept a (9) zone, (2) pass IR Dryer with slide out drawer to access the dryer lamps.

- Docking stations for multiple locations, power connectors to plug into docking stations and a pin-and-puck system for accurate level and tram positioning with fork lift inserts for portability

Options available are:

- The (3rd) motorized carriage with bucket per rail

- 2nd chill roll assembly

- Additional power docking stations

- Pin-and-puck systems for multiple locations

- Buckets to house alternative Ink Jet Heads

Scheffer International Products

© Scheffer International • 1155 Arrowhead Court • Crown Point, IN 46307 • Phone: (219) 736-6200 • Email: sales@scheffer-international.com